Supply chain of Animex

Breeding farm

Only pure white geese are reared in Poland.

No grey geese are reared (except by individuals). Thanks to decades long DNA improvement process, the species of Polish white goose is recognized all over the world.

Hatchery

As soon as the eggs arrive at our hatchery, an important stage, consisting of two phases: incubation and hatching, begins. The most important factors during this time are humidity, temperature and the appropriate frequency of egg rotation. The incubation period for our geese species is 31 days.

Livestock farm

The Polish White Kołuda Goose (oat-fattened) is reared in completely natural conditions. Vast green pastures, free access to water and natural nutrition translate into the uniqueness of the final product, which is the globally valued Polish white down. Poland's climatic conditions, with hot summers and frosty winters, are conducive to the development of thick plumage. Goose feathers are designed to protect not only against cold in winter but also against overheating in summer. In Poland, geese are reared on family farms with many years of breeding traditions. Polish white oat-fattened geese are reared on a free-range basis, which allows the birds to enjoy freedom and stress-free life. Its feathers are characterised by high thermal insulation, beautiful white colour and long life.

Processing plant

Although mechanical picking is the easiest way to remove feathers, we do not hold to our unique principles In order to maintain the highest quality of raw material, we use a unique method of post-mortem, manual removal of feather cover. It is a time-consuming and costly process, but it allows to fully preserve the natural structure of down. It also greatly reduces the amount of fiber and damaged feather.

Feathers

The exceptional technology of dividing into fractions means that different types of raw material are separated and processed individually.

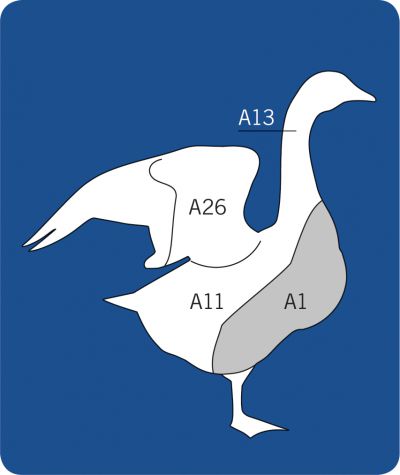

We distinguish and separate four fractions of feathers of different structure:

- A1 - abdominal and thoracic

- A13 - neck

- A26 - wing

- A11 - side

This technique makes it possible to extract the best quality characteristics from each of these feathers. The method of obtaining feathers is unique in the world.

Feather processing plant

Processing of raw material into top-quality down requires a combination of appropriate knowledge, specialist skills and professional machines for processing goose feathers. Naturally, we combine all these qualities to produce a world's unique down.

The production process involves:

- Washing - the raw material is thoroughly cleaned of any surface deposits and residues, so that it can be sterilised.

- Sterilisation - a very precise removal of any microorganisms and mites to ensure that the filling is as clean and non-allergenic as possible

- Sorting - a precise process of separating down from feathers and mix of down and feathers. It is especially important for obtaining high-quality down.

- Dust removal - a process that consists in removing excess dust and down feathers (single pieces of down and feathers). In addition, in order to obtain the highest quality, we also use manual sorting of down.

Production planning

Production and warehouse management in our plant is based on the SAP system, where each single bag receives an individual label containing complete data that enables precise identification of the origin of the origin, type, quantity and quality of raw material. Based on this data and its analysis, production plans are drawn up for each batch, determining the quality, quantity and intended use for a specific customer or market. The IT system is equipped with modern recording stations and scanners, which allows to eliminate the risk of mistakes and improve work efficiency and deliver the finished product to our customers.

Quality control

Quality control is the responsibility of the in-house laboratory performing a full range of tests to verify for example:

- purity,

- resilience,

- percentage of down,

- fat content,

- moisture content,

- pH,

- organic matter content

- others

Our laboratory carries out control at three stages of production:

- immediately after acceptance of the raw material in order to verify its original parameters

- during processing phases; for the control of the processing process

- after the final product is obtained; to confirm the final parameters of the produced down

In order to verify the quality of our products, we compare our reports and exchange knowledge with external research institutes and independent laboratories, such as IDFL Europe, IDFL USA and Q-TEC Japan.

Sustainability

Animex pursues the principles of sustainable development in accordance with the well-known motto "think globally, act locally". We care about the development of our company, its global character and presence on global markets, while not forgetting about the immediate environment in which we operate.

Animex has set goals to be achieved in six areas of sustainable development, the monitoring and accomplishment of which ensures that the Company's mission and strategy are implemented, and that local communities and the environment also benefit from it.

The main areas of sustainable development are:

- product safety

- safety of employees

- animal care

- environmental protection

- supporting the local community

- creating added value for the company and its immediate environment.